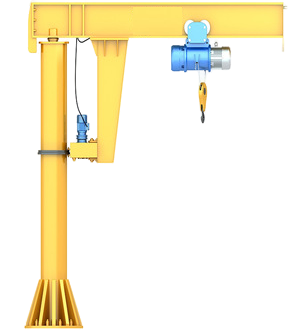

JIB CRANE

JIB CRANE

We are engaged in manufacturing a range of Jib Crane that is designed and developed using latest technology and quality components. These Jib Cranes have a rotating boom to a mast and ceiling mounting. The rotating boom is held in a vertical position by floor and the ceiling mounting by wall bracket mounting. Jib crane stands for superior quality product. They are an important part of any material handling system. They help reduce labour cost by avoiding the time lost on waiting for an overhead crane or forklift. A Jib crane can be easily handled by one person and is very cost-effective. By combining lightweight construction techniques we have developed a Jib crane that is not only lightweight but produces minimum amount of friction thus reducing operator fatigue and wear and tear. These cranes are widely used for heavy machine loading, material loading & unloading, light assembly work and many other applications. Our products are known for their sturdy construction and durability and are offered to our customers at industry leading prices. An integral part of any material handling system, these cranes have a rotating boom to a mast and ceiling mounting. Moreover, the rotating boom is held in a vertical position by floor and the ceiling mounting is held by the wall bracket mounting.

Features

- Heavy Duty Jib Cranes are base mounted; self-supported jibcranes with thick base plate mounting on a concrete foundation with 220° rotation of jib arm.

- These types of cranes are widely used in Fabrication Shops Machine Shops Assembly Shops loading & unloading purposes and can be used both indoor as well as outdoor applications.

- A set of taper roller bearing in combination with thrust bearing one set at bottom and one set at top take care of horizontal and vertical load as well as radial thrust.

- Jib cranes are available with hand operated or electrically operated chain pulley block for vertical lifting and chain operated or electrically operated gear trolley for horizontal movement of load.

- MS gusset plate

- Double roller self-align bearing

- Rolled pipe steel sections

- Standard bearings

- Special polyurethane shock absorber or buffers are provided at extreme ends as a standard feature.

Specifications

| Model | Unit | REC-408 |

| Capacity | Tons | 1 to 5 |

| Max Lifting Height | mm | As Per Requirement |

| Length | mm | As Per Requirement |

| Width | mm | As Per Requirement |

| Height | mm | As Per Requirement |